Programmed for success.

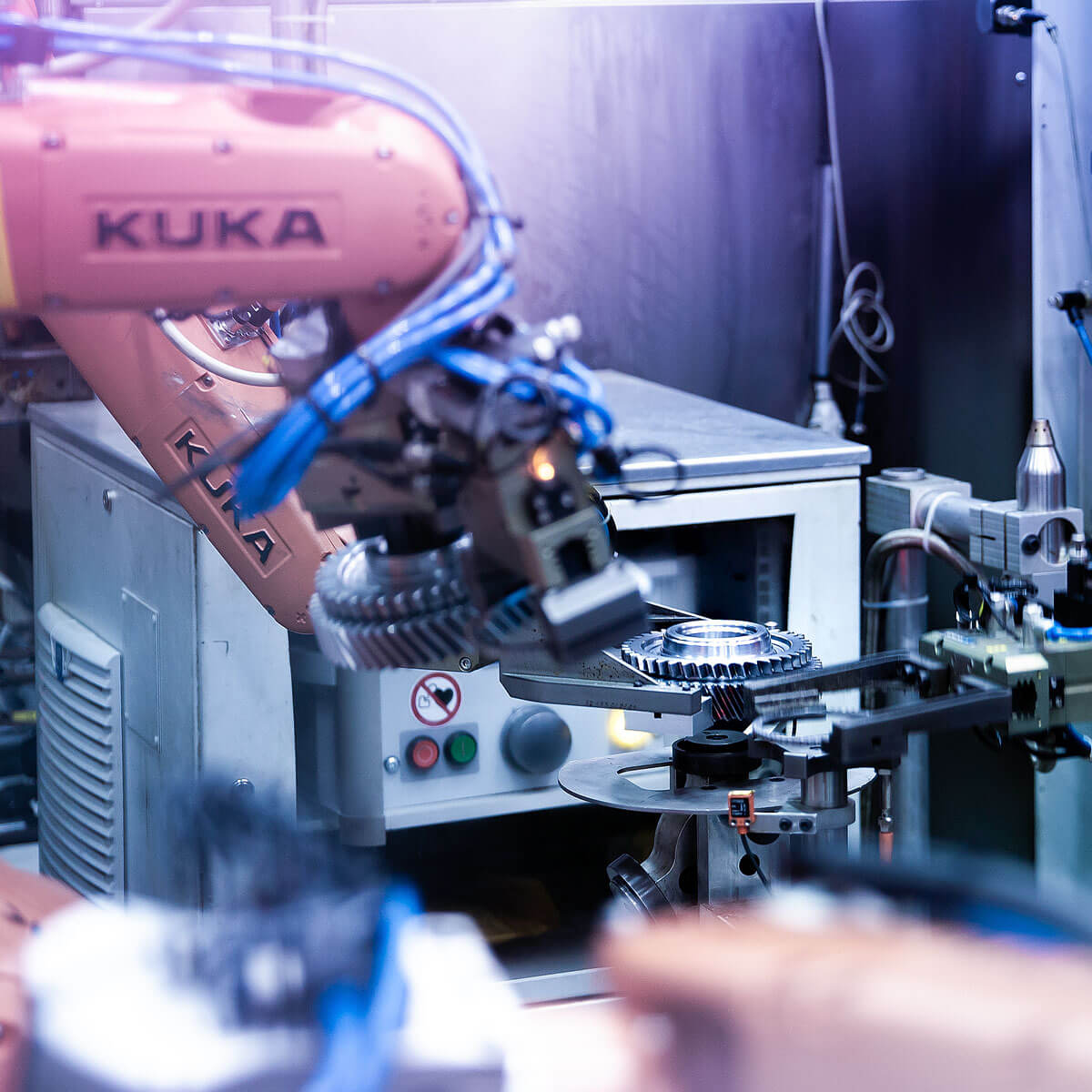

For process reliability and cost-efficiency, automated workflows with state-of-the-art robotics are indispensable. After all, the higher the degree of automation, the more reliably defects can be prevented. For this reason, Stelter automates almost all the process steps in gear manufacturing and heat treatment in its own heat-treatment facility with a variety of industrial robots and loading and unloading systems. Stelter does not differentiate between the sizes of the components to be moved and even moves gears weighing a ton for the wind power and rail industries in fully automated fashion.

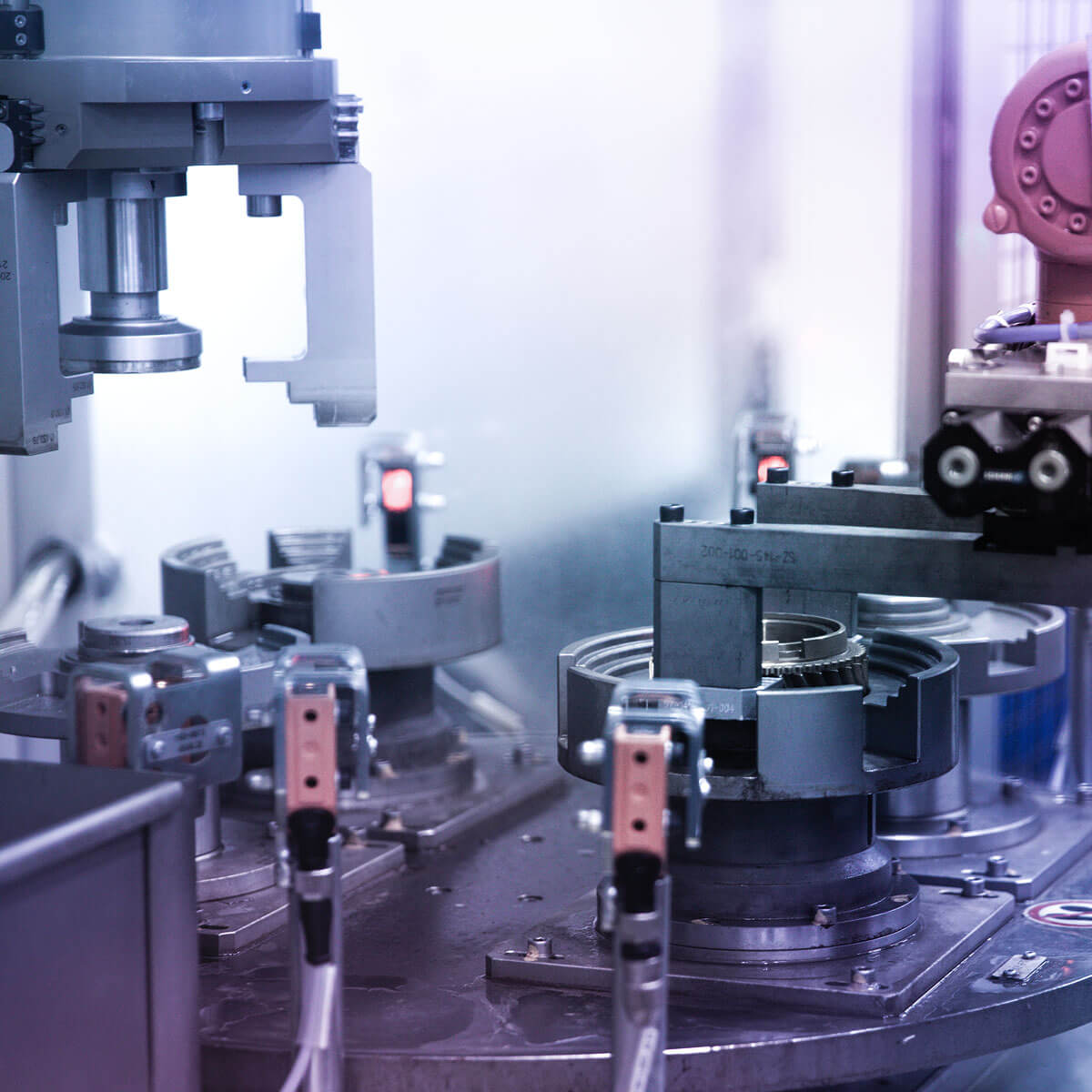

Consistent automation is extended at Stelter with an intelligent blank supply system in the large-scale production of automotive components, in which numerous machines along the process chain for soft machining, amongst other things, are connected to an EWAB shuttle system. Customers who order large batch sizes from Stelter benefit in particular from this automated series production.

In addition to gear manufacture, many quality checks and washing/marking processes are fully automated at Stelter.