Soft machining

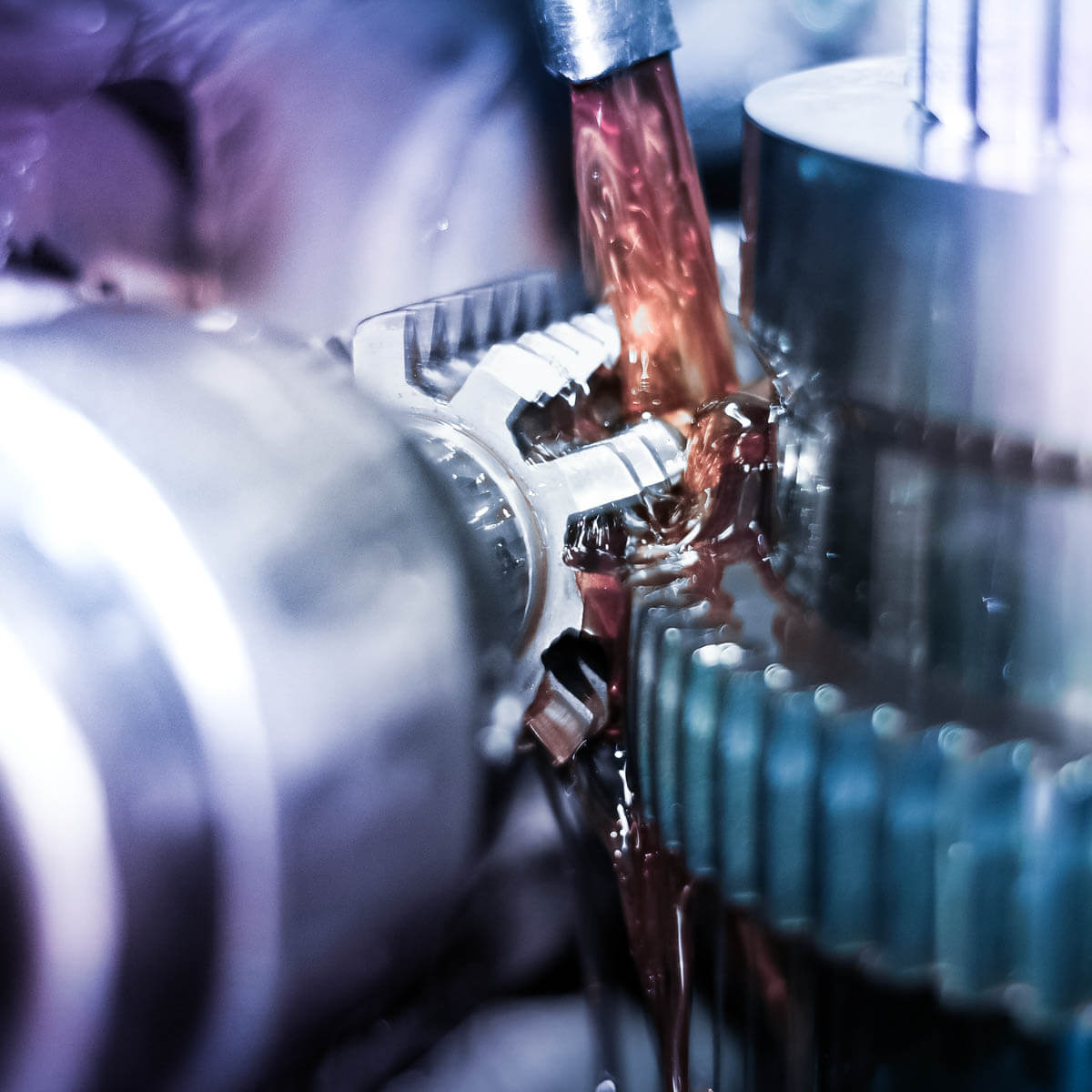

Gear cutting

The technology at a glance.

- Automated CNC gear hobbing machines with modern industrial robots are used from various reputable machine manufacturers.

- The production range spans from module 0.5 to 44, with a max. tip diameter of 1,600 mm and a length of 1,000 mm.

- Worm shafts and worm gears can be geared to module 2.75.

- The toothing of gears and shafts is performed both in wet and dry processes, even without cooling lubricant.

- During gear milling, the burr is disposed of either simultaneously using deburring steel, with an integrated deburring station or by burr removal through rolling after the toothing.

- Hobs are sharpened in our in-house tool reconditioning operation.